Methodology

What are natural vegetable fibers?

These are fibers obtained through the extraction and processing of plant materials, possessing a fibrous structure that allows them to be transformed into various products.

Fieldwork

We visited different communities to learn about the material, the extraction process, and the crafting of handicrafts through interviews, observation, and training workshops.

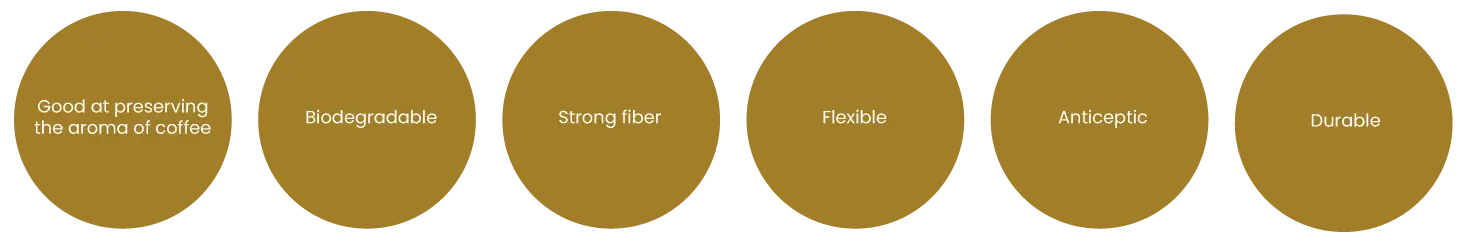

Why Fique?

Findings from research

Fique crops benefit between 50.000 to 70.000 families around Colombia.

It is the most popular natural fiber in Colombia.

The fique has a waste (bagasse) rate of 85% to 90% of the total plant during the defibering process

The bagasse has a serious environmental impact.

Historical and cultural importance to the country.

It has a very low price in the market.

The fique is a succulent plant with thorny and sharp leaves. Through the extraction of fique, artisans make threads.

Location: It is grown in 13 Colombian departments, most of them in the Andean region: Cauca (36.26%), Nariño (27.61%), Antioquia (7.8%), Santander (23.9%), Boyacá (0.5%), Cundinamarca, Caldas, Risaralda, Quindío, Tolima, and Huila (0.24% combined).

Uses: Ropes and leashes, sacks, espadrilles, nets, backpacks, bed linens, furniture finishes, mattress filling, shoe soles, thermal insulation, paper, packaging, belts, baskets. Natives used fique for human and veterinary medicine and even as a drink.

Features: Resistant, withstands humidity, flexible, malleable, durable, variable, dyeing capacity, biodegradable, antiseptic, preserves the characteristics of coffee.

Problems:

Customer

Journey map

Empathy

Map

Pains

Raw material is very cheap to sell, a lot of material is wasted, and there is a lot of competition between artisans.

Wishes

More income, valuing artisan products and processes, and preserving artisan traditions.

Needs

Better processes, innovation, more income, the need for more customers, and less risk for employees.

Challeneges

Competition, pests, weather conditions, low material prices, and high process expenses.

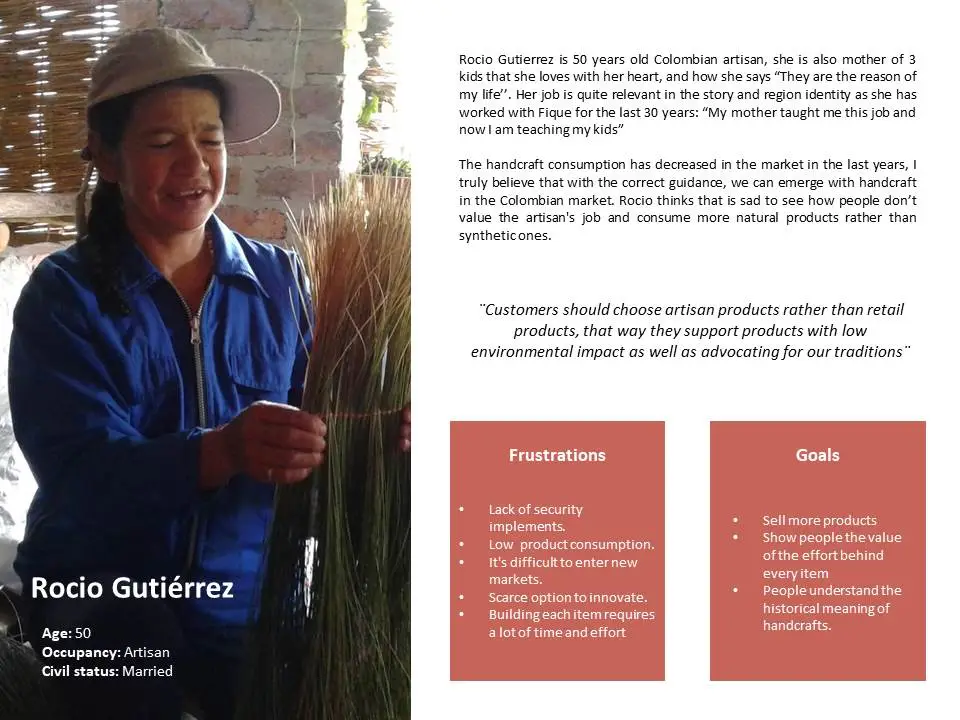

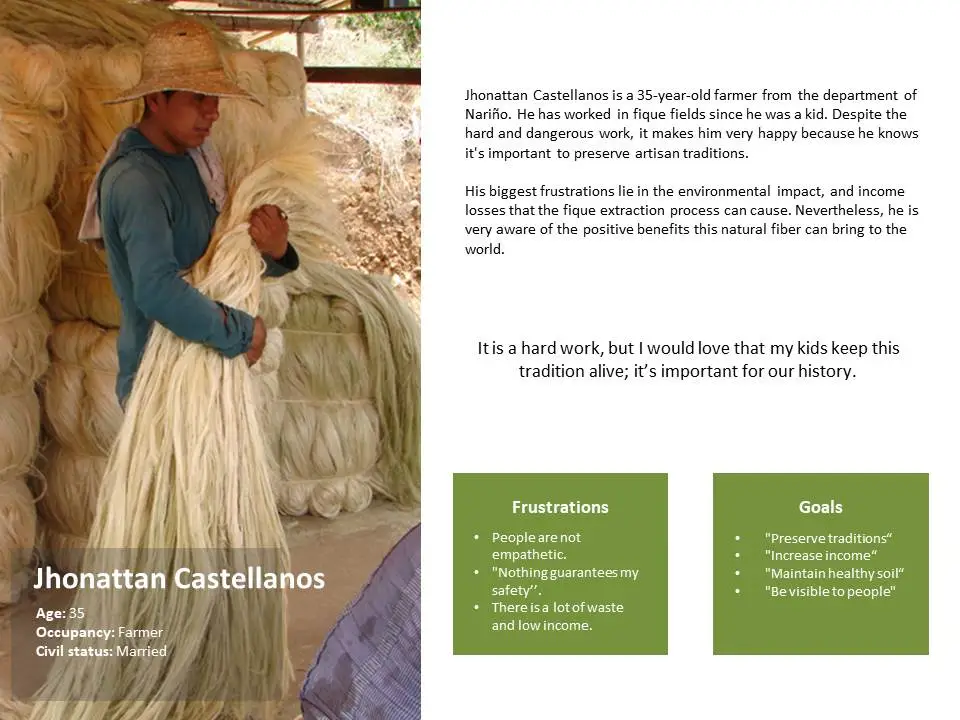

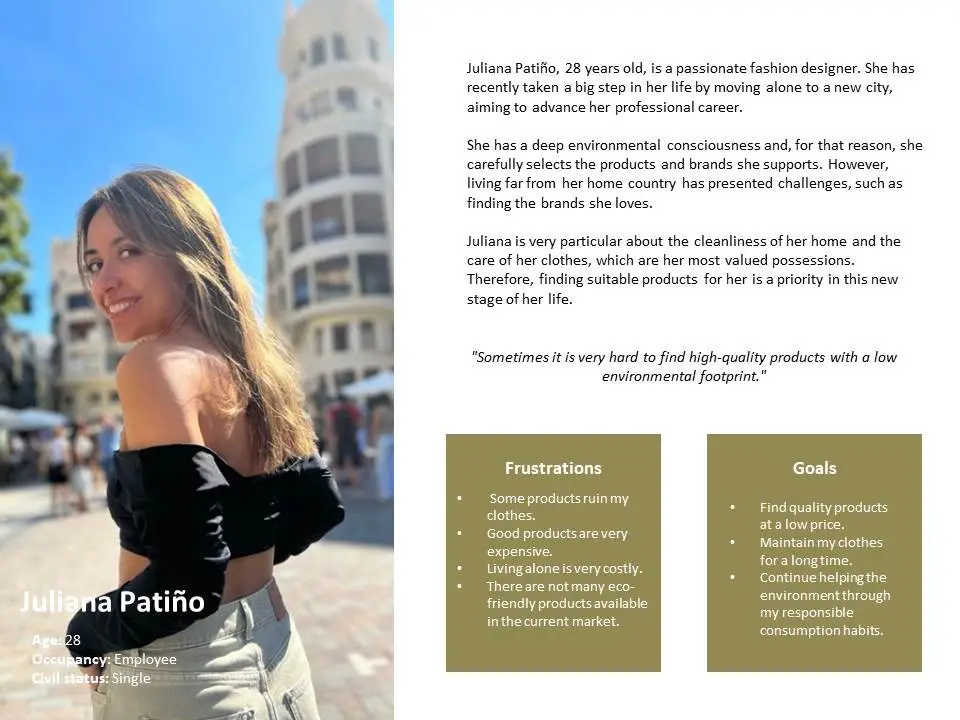

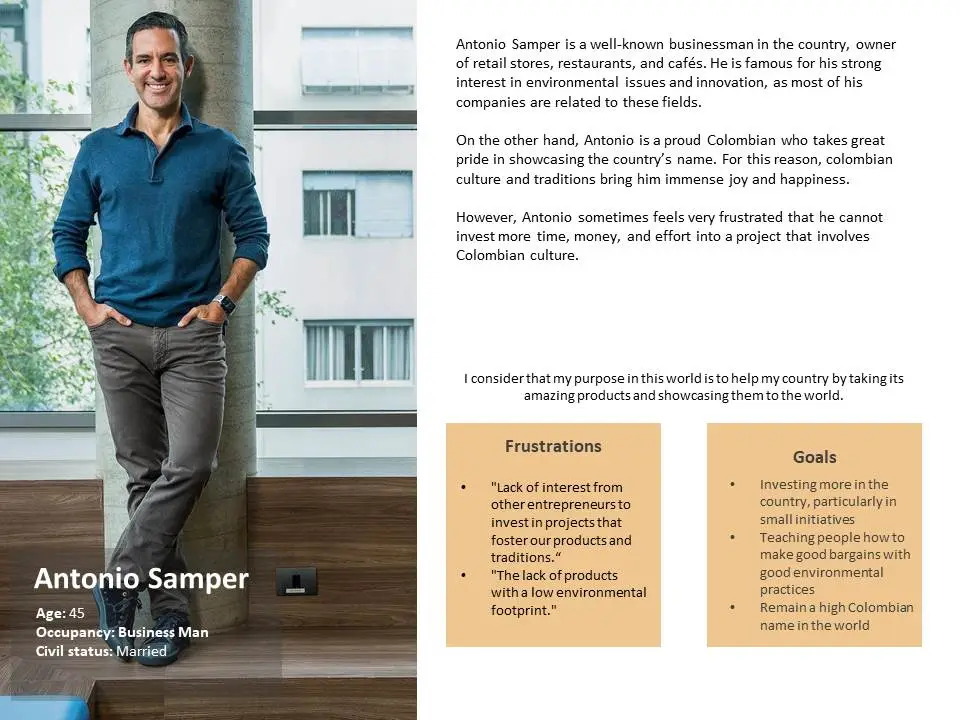

User persona

Design

Process

Opportunities

Challenges and constraints

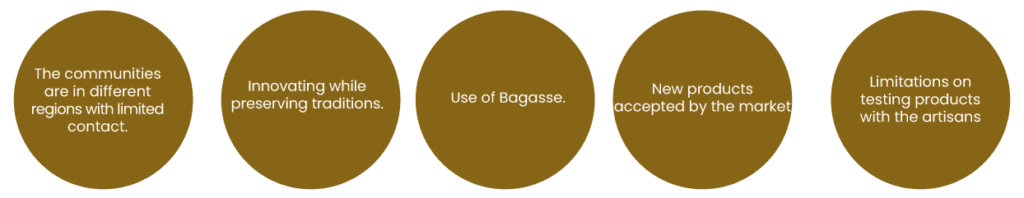

Material development

2. Soften the bagasse

3. Blend the bagasse

4. Obtain a paste

5. Cassava starch or popatoe starch

6. Mix the startch and the a paste

7. Make a molde

8. In this case is the base of plastic bottle

9. Set the mix in the mold and let it dry for 3 days

Final project

launch

To display the products in the market, we chose well-known brands in the country (such as Carulla as an example of a supermarket and Juan Valdez as an example of a coffee shop) for branding design and exposure.

A mimbre structure in a hyperboloid shape, made from fique and cassava starch, designed to create an atmosphere of comfort, connection with nature, and cultural traditions, based on characteristics of transparency and biomimicry, evoking the shape of a flower.

Ergonomic design of natural laundry soap: 15% fique juice, lavender fragrance, and smooth texture. Its shape adapts to the grip of the hand.

Takeaways: The ‘Bio-Maguey’ project highlighted the importance of collaborating with artisan communities to create culturally relevant and sustainable designs by utilizing waste materials like fique bagasse. The experience emphasizes the value of blending traditional techniques with innovation, adapting to the limitations of natural fibers. As a result, a line of biodegradable products was created that not only economically benefits local communities but also preserves cultural heritage and promotes circular economy practices, achieving modern and authentic market acceptance.

Acknowledgments

I want to extend my sincere grattitude to the Nariño and Boyacá communities and their artisans for revealing the beauty of fique craftsmanship, showcasing the versatility and features of this fiber, and highlighting its significance to our culture and regional development. Thanks to your help and teachings, we were inspired to create Bio-Maguey, and we hope it inspires you to continue the legacy of using natural fibers.